John Peter Nicholson, Eurocorr 2010

Summary

With today’s electronic instrumentation, it is possible to combine close interval potential surveys (CIPS) with direct current voltage gradient surveys (DCVG) of buried and underwater pipelines for improved accuracy in assessing the level of cathodic protection combined with locating coating defects without spatial errors. Modern electronic survey instruments are capable of stamping each reading with the time, date and submetre

GPS coordinates. This provides information for accurate mapping of the pipeline location, current state of the cathodic protection system, and further allows personnel to accurately locate areas requiring excavation for coating repair. This paper will show by example how combined CIPS and DCVG surveys undertaken to NACE standards are of benefit to pipeline operators in ensuring cost- and time-effective integrity management of their pipeline systems.

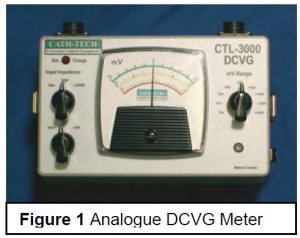

Traditionally direct assessment of external corrosion of pipelines has been undertaken as a two step process with a close interval potential survey (CIPS) undertaken to determine

the level of cathodic polarization and an analogue (See Figure 1) direct current voltage gradient (DCVG) survey to determine the location of coating defects or holidays. Undertaking the CIPS and DCVG surveys separately leads to spatial errors.

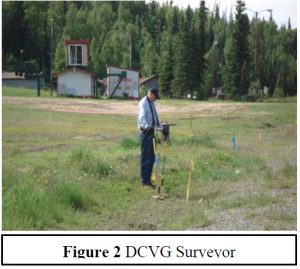

Further, if the surveys are not done concurrently, errors can result due to differences in soil moisture content, the skill of the operators undertaking the survey, changes in the level of cathodic protection and the inability to accurately mark or record the location of coating defects, they must be manual staked out. (See Figure 2).

John Peter Nicholson

NACE Accredited Senior Corrosion Technologist

Managing Director

Cathodic Technology Limited

15-1 Marconi Court

Bolton, Ontario, Canada, L7E 1E2