Download PDF

Peter Nicholson, Pipeline Rehabilitation & Maintenance, September 2006

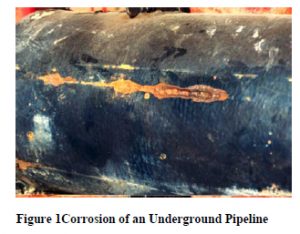

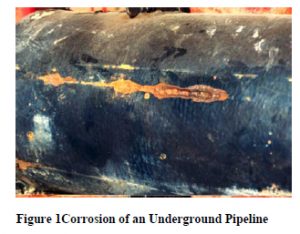

All underground/underwater metallic pipelines are subject to corrosion where there are inadequate levels of cathodic protection. Cathodic protection is the only method of reducing or halting external corrosion on underground/underwater pipelines.

NACE International through Standard Recommended Practice RP0-502 has developed a five step approach to corrosion control of underground/ underwater metallic pipelines, this process is known as External Corrosion Direct Assessment (ECDA). The ECDA process is as follows:

External Corrosion Direct Assessment is a five-step

process as follows:

1. Pre-Assessment (Gather Information on the System)

2. Indirect Examination (Gather Data on System)

3. Direct Examination (Excavation of Priority Areas)

4. Remediation (Repair or Replacement)

5. Post-Assessment (Effectiveness of Remediation)

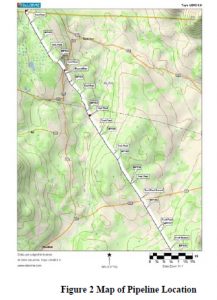

Pre-Assessment may include mapping the physical location of the pipeline, its appurtenances, test facilities, valves, pump stations, take-offs, test stations, bonds, rectifiers, etc.

Indirect Examination may include historical information on the operation and maintenance, repairs, damage and other factors that may influence the longevity of the pipeline system. The indirect examination may also

include operating pressures (stress) metallurgy of the pipeline system and its susceptibility to hydrogen embitterment and stress corrosion cracking.

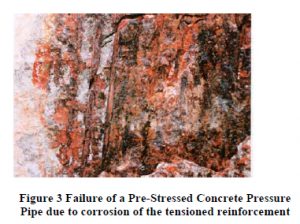

ECDA is not limited to steel or iron pipelines but should be applied to reinforced concrete pipelines as well.

Direct Examination may include the use of the ECDA tools to determine the effectiveness of the cathodic protection system, the condition of the protective coating and if warranted the excavation of areas where the level of cathodic protection is inadequate.

Remediation and repair may include improvements to the cathodic protection system to increase the level of cathodic protection as well as repair of coating defects or refurbishment of the protective coating or replacement of pipe sections if warranted.

Post Assessment would include a close interval potential survey to verify the effectiveness of any coating repair, pipe replacement or improvements to the cathodic protection system.

ECDA tools commonly used include:

- Close Interval Potential Surveys (CIPS)

- Direct Current Voltage Gradient surveys (DCVG)

- Alternating Current Voltage Gradient surveys (ACVG)

- Current Attenuation

- Pearson Surveys

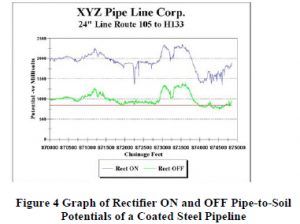

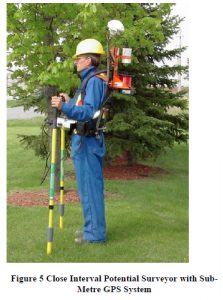

Close Interval Potential Surveys (CIPS) is the only effective method of determining the level of cathodic protection on underground /underwater metallic pipelines.

All other survey methods indicate coating integrity, which is not indicative of the level of cathodic protection on an underground/underwater pipeline.

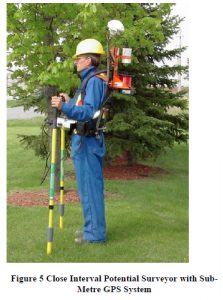

A close interval survey is the measurement of the rectifier ON and Instant OFF potentials (IR Free) along a pipeline cathodically protected by an impressed current cathodic

protection system, or the measurement of, the polarized potential of a pipeline in the case of a sacrificially protected pipeline. Potential readings are correlated with distance and GPS coordinates and are usually recorded on a 1 to 3-metre interval directly over the pipeline under test.

A close interval potential survey undertaken with all rectifiers influencing the survey area synchronously interrupted utilizing the GPS timing signal reveals the true

Cathodic Technology Limited Ontario Canada 3 polarized potential of the pipeline and any defects in the cathodic protection system.

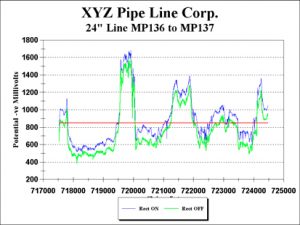

Fig 5: Potential Profile of 30 Year Old Pipeline showing sub-criterion potentials

Figure 5 shows the potential recorded on a 30-year-old pipeline. The potentials at test stations where sacrificial anodes have been installed to supplement the impressed current cathodic protection system falsely indicate that the pipeline is cathodically protected.

Direct Current Voltage Gradient Surveys (DCVG) is the application of a pulsed DC current either from the interruption of the cathodic protection rectifiers or the application of pulsed DC current from a temporary source. Voltage gradients are measured along the pipeline. DCVG surveys have traditionally been undertaken utilizing an analogue instrument.

Figure 6 Analogue Direct Current Voltage Gradient Survey Instrument

A direct current voltage gradient is generated by direct current flowing through the soil to a defect in the coating from a source of direct current power such as a rectifier or

temporary power source. The magnitude of the voltage gradient is determined by Ohms Law (E=IR), where E is the voltage gradient, I is the current flow through the soil

between the measuring electrodes and R is the resistance of the soil circuit between the measuring electrodes.

Generally the larger the voltage gradient the larger the coating defect, but soil resistivity and current attenuation must be considered in the interpretation of the magnitude

of the voltage gradient. DCVG surveys do not indicate the level of cathodic protection on a pipeline system.Alternating Current Voltage Gradient Surveys (ACVG) are identical to DCVG above only an isolated AC power source is used to supply current to the pipeline for the measurement of the voltage gradient. AC voltage gradient surveys do not indicate the level of cathodic protection on a pipeline. Defects in the pipeline coating are usually marked with flags and their location chained at the end of the day or survey.

Current Attenuation is the measurement of the current attenuation on a pipeline with distance from the power source. The current attenuation is indicative of the coating quality and integrity. Current attenuation does not indicate the level of cathodic protection or the effectiveness of the CP system.

Pearson survey is an electrical method of locating holidays in a pipeline coating by the application of an AC signal on a pipeline and the reception of the signal by two surveyors wearing metal cleats and connected to the Pearson receiver.

Traditional Survey Methods

Test station surveys have been traditionally used to indicate the level of cathodic protection on a pipeline.

Figures 5 and 8 graphically indicate how Reliance on test station surveys can lead to corrosion and pipeline failure.

Close Interval Potential Surveys (CIPS) have been utilized to supplement test station surveys determining the level of cathodic protection on underground /underwater pipelines.